Overview

With the continuous improvement of the automation and intelligence level of textile and garment production, a lot of automatic control equipment and power electronic equipment have been applied to the textile production line. A lot of high-tech operations, from spinning to weaving, used a lot of variable frequency speed control devices in the entire production process, and a lot of adverse effects on the production line:Leading to the failure of automatic control equipment and power electronic equipment heating temperature control failures in the production line of nylon slices, sizing machines, doubling machines, automatic winders, combers, blow-carding equipment, twisters, etc., resulting in a serious degradation of product quality , Causing huge economic losses to the enterprise; causing serious heating of electrical components such as transformers and busbars in the distribution room, causing great hidden dangers.

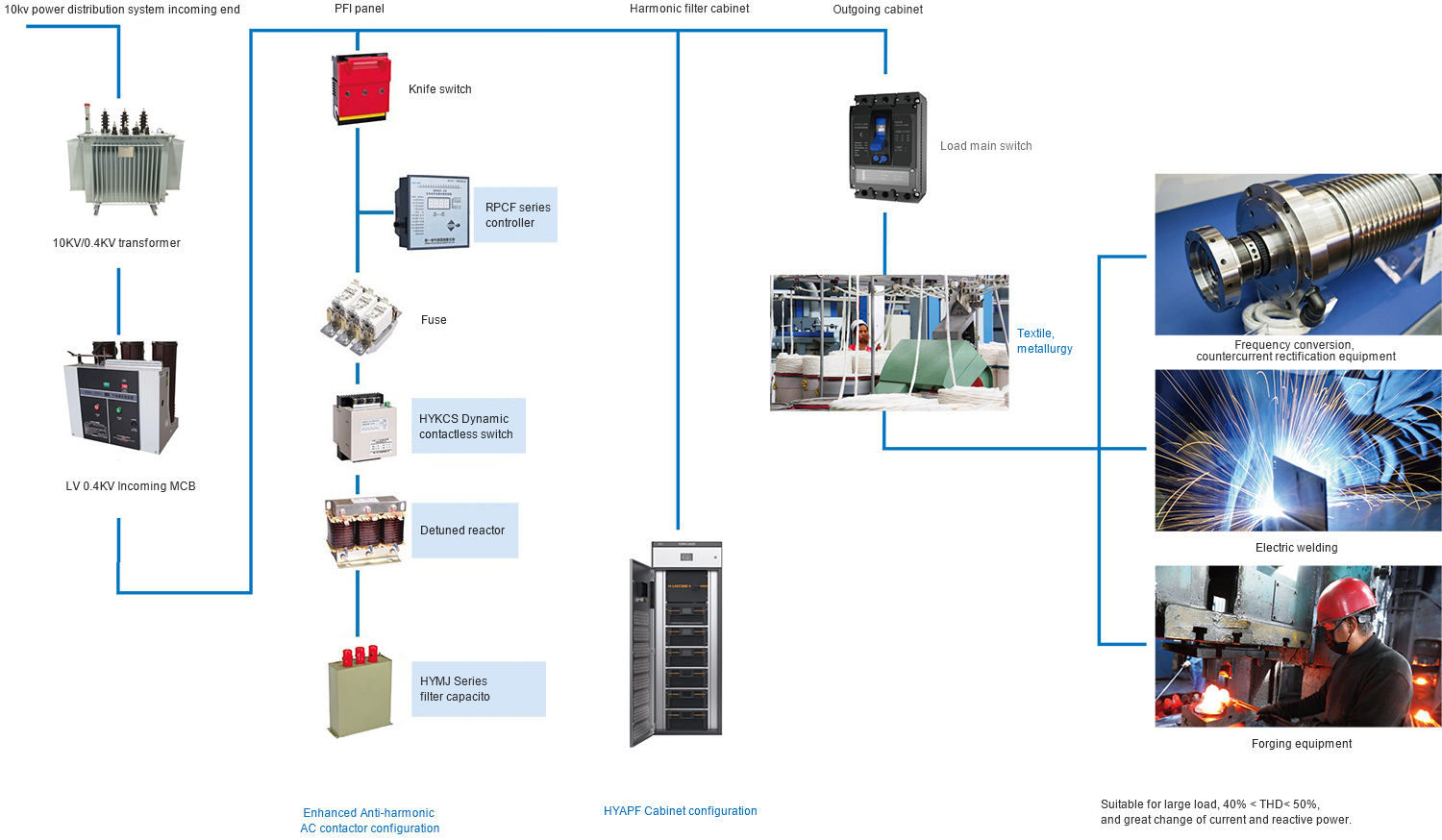

In a large textile mill, our HYKCS dynamic contactless switch is used to switch capacitor panel, which has no inrush current, no oscillation and fast response, At the same time, using active power filter device(HYAPF), all harmonics can be effectively filtered out and reach national standards, and the average power factor can reach 0.98 and above, which improves the utilization rate of transformer, reduces the line calorific value of the whole power distribution system, and reduces the failure rate of electrical components and production equipment.

Scheme drawing reference

Customer case