Overview

Automobile production workshops (pressing workshops, welding workshops, assembly workshops.) use a lot of non-linear loads such as electric welding machines, laser welding machines and large-capacity inductive loads (mainly electric motors), As a result, the load current of all transformers in the workshop has serious harmonic current for 3rd, 5th, 7th, 9th and 11 th. The total voltage distortion rate of 400 V low-voltage bus is more than 5%, and the total current distortion rate (THD) is about 40%. The total voltage harmonic distortion rate of 400V low-voltage power distribution system seriously exceeds the standard, and leads to serious harmonic power of electrical equipment and transformer loss. At the same time, the load current of all transformers in the workshop has a serious demand for reactive power. The average power factor of some transformers is only about 0.6, which leads to serious power loss and serious shortage of output active power capacity of the transformer. The interference of harmonics makes the automatic production system of automobile Fieldbus unable to work normally.

An automobile manufacturing branch company adopts HYSVGC intelligent power quality comprehensive management device and active power filter device(APF), It can effectively and quickly compensate reactive power, the average power factor can reach 0.98, and all harmonics can be filtered according to national standards, which improves the utilization rate of transformer, reduces the line calorific value of the whole distribution system, and reduces the failure rate of electrical components.

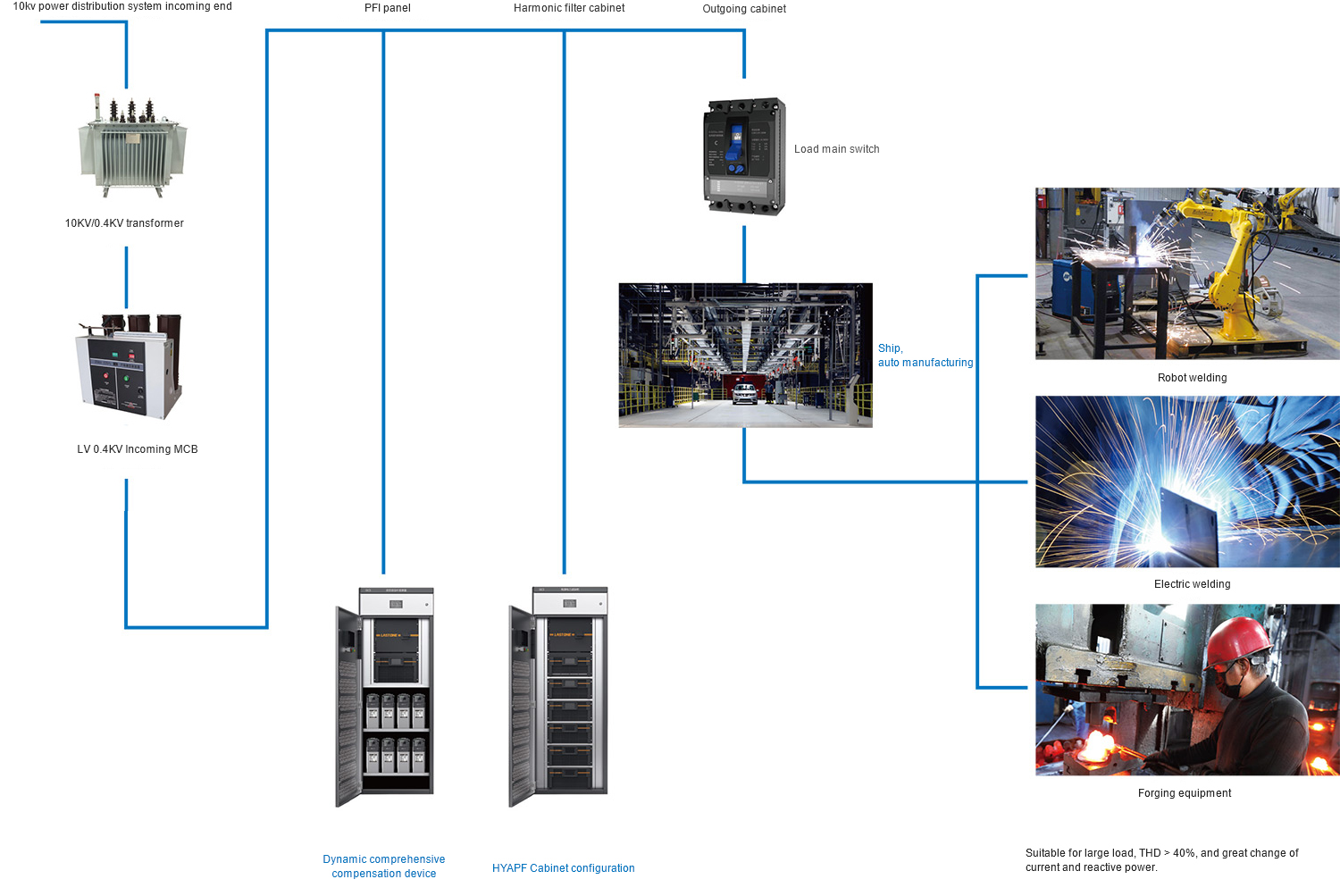

Scheme drawing reference

Customer case